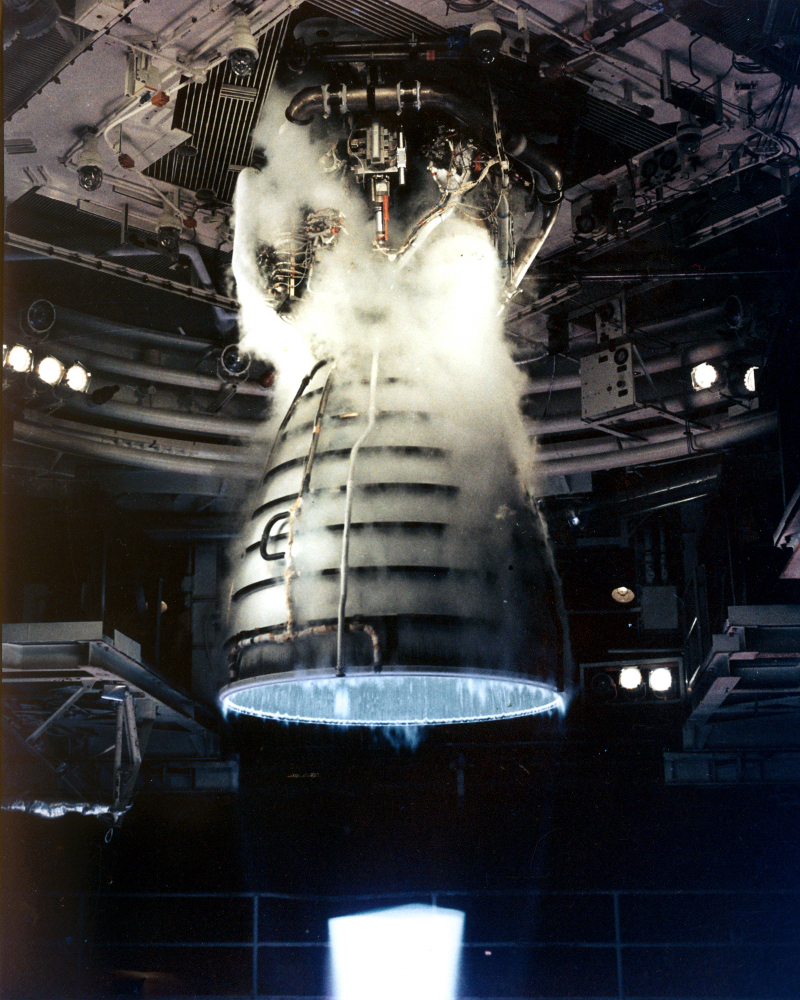

The complexity of aerospace systems is increasing exponentially. Both hardware and software subsystems are becoming more complex and encompassing systems’ behaviour becomes difficult to model due to the dependencies, relationships, and other interactions between their components. Predictable behaviour of complex aerospace systems translates into the reliability of each of their subsystems.

According to published reports the amount of total counterfeiting globally has reached 1.2 trillion USD in 2017, and it is predicted to reach 1.82 trillion USD by 2020. Counterfeiting affects all industries, aerospace and defence included. It turns out that identifying counterfeit components in the aerospace and defence supply chain is really challenging. In 2011 it was estimated that up to 15% of spare parts and replacement used by the US military were counterfeit. In a 9-page report dated November 4, 2016, obtained by Reuters through a freedom of information request, the Federal Aviation Authority (FAA) said 273 affected parts were installed in an unspecified number of Boeing 777 wing spoilers.

Having counterfeit components entering the aerospace market leads to decreased reliability of subsystems used in the aerospace industry. The consequences of using unreliable components in the aerospace and defense industries should not be underestimated or ignored for that matter. Parts that are manufactured for launch systems, spacecraft, aircraft, and weapon systems, and do not meet the required specifications should stay out of the supply chain.

There are various counterfeiting methods. Just to give an example, counterfeiting methods employed in the electronics supply chain include:

- Remarking of new or already used components with false manufacturer names, part numbers, date codes, lot numbers, quality levels. One way to identify remarked electronics is to engage the original manufacturers. However, there were cases when remarking was performed by the original manufacturer.

- Reuse of already used components. The increasing recycling of electronics is causing this trend. Certain countries import used electronics and return to the marketplace components removed from the discarded circuit boards.

- Outsourcing production to production facilities that are not employing proper testing or do not meet specifications.

- False approval markings used by manufacturers that skip the required certification process.

In order to protect itself, the aerospace and defense industry enforces quality management systems standards. The AS9100 standard is a quality management systems standard that includes requirements for aviation, space, and defense organizations. The AS9100 standard includes ISO 9001 quality management system requirements and, in addition, specifies aviation, space, and defense industry requirements. It is important to note that the requirements contained in AS9100 are complementary to existing customer or applicable statutory and regulatory requirements. Also, the customer or applicable statutory and regulatory requirements take precedence. The requirements of the standard are applicable to any organization, regardless of type, size, products or services it provides.

AS9100 defines counterfeit product as “An unauthorized copy, imitation, substitute, or modified part, which is knowingly misrepresented as a specified genuine part of an original or authorized manufacturer. NOTE: Examples of a counterfeit part (e.g., material, part, component) can include, but are not limited to, the false identification of marking or labeling, grade, serial number, date code, documentation, or performance characteristics.”

How is AS9100 helping combat the acceptance of counterfeit components in the aerospace and defense supply chain? A number of AS9100 clauses provide requirements relating to the mitigation and prevention of counterfeit components. These clauses are Counterfeit Part Prevention, Control of External Providers, and Information to External Providers. The Counterfeit Part Prevention clause states: “the organization shall plan, implement and control a process appropriate to the product that prevents the use of counterfeit product and either inclusion in product(s) delivered to the customer.”

Also, the Control of Nonconforming Outputs clause requires “counterfeit, or suspect counterfeit, parts shall be controlled to prevent reentry into the supply chain. Unsalvageable and counterfeit parts shall be conspicuously and permanently marked, or positively controlled, until physically rendered unusable to prevent restoration.”

The aerospace industry continues to allow manufacturers to maintain sole responsibility for their own manufacturing records. Also, the proliferation of practices known as “source delegation” and “self-regulation” place the responsibility for supporting documentation solely in the hands of suppliers. While the above-mentioned AS9100 clauses can help alleviate some of these issues, there is an immediate need for supply chain traceability. Employing an industry-wide supply chain database and guaranteeing access to all quality-related documentation seems to offer effective means for countering counterfeit components in the aerospace and defense industry.

References and other useful links:

Counterfeit examples for electronic components

Wikipedia article on AS9100 standard

Quality digest article on AS9100 standard

Subscribe to blog posts using RSS

Subscribe to blog posts using RSS