Today we are joined by Logan Ryan Golema, Founder & Principal, and Vishal Singh, Chief Scientist at Lunargistics. Lunargistics is the Space Division of Hercules Supply Chain Protocol, and it is aiming to provide swift logistics in cislunar space. Logan and Vishal were kind to answer a few questions about Lunargistics and the supply chain in the cislunar space.

Orbital Hub: How big of a risk are the counterfeit components in the aerospace supply chain?

Logan Ryan Golema: You’d be surprised, I know I was. The Aerospace industry has three types of companies; those that make their own parts, those that buy their parts, and those that sell parts. And some of them do all three! These industries are often involved with local manufacturers hence the risk of fraud is very high.

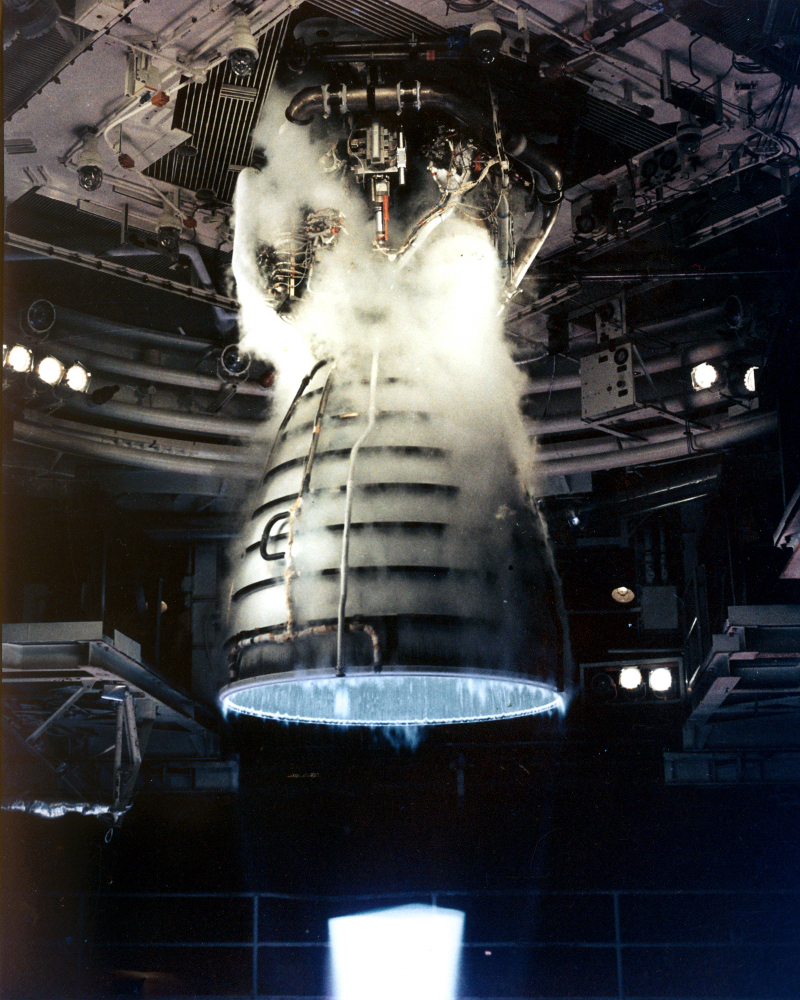

Vishal Singh: More often than not everything is OK and well documented, but when there’s a mistake or a fraudulent document on a fake part disaster can happen. Those disasters can be catastrophic as any aerospace structures when in air or in orbit can take lives on land catastrophically. So if a fraudulent document or some error comes it is a man made disaster. When we talk about a space mission; an inch of error in calculation due to fraudulent documents can lead to a war between States or even worse taking lives of thousands of innocents.

O.H.: How is blockchain technology used to mitigate the risk of counterfeit components in the aerospace supply chain?

L.R.G.: Blockchain solves a lot of issues; from fraudulent documents to manufacturing and maintenance of Airplanes to rockets. It is like providing a birth certificate and an IMEI to each component and will result in understanding the root cause of every single problem occurred while in flight or in manufacturing.

V.S.: Let’s take the example of India’s ambitious mission Chandrayaan-2, which failed probably due to failure of power and communication systems. Using the blockchain in the industry will make the “may” in the statement a definite answer to the cause of failure.

O.H.: What blockchain infrastructure is Lunargistics using?

L.R.G.: Lunargistics will be leveraging the Hercules Blockchain Protocol (https://herc.one). Onboarding existing Aerospace companies in Europe and across the globe to this powerful tool with Enterprise level APIs and high performance apps is our aim. We’re set up with the client in mind so they can focus on their mission while we handle the blockchain side of things.

O.H.: What are the defining features of this blockchain infrastructure?

L.R.G.: The interoperability and layering of modular based components. The Hercules Protocol acts sort of like a LAMP stack of old. Today with Lunargistics managing your HERC stack you’ll have:

– indisputable data integrity,

– timestamped uploads,

– files that will be accessible without fail,

– portfolios of persons involved in the manufacturing of something so small as a screw to the powerhouse of an engine.

It’s like having the birth certificate and report card of each component. By having a blockchain system based on the Hercules module will lead in minimising the failures like Israel’s moon mission and Chandrayaan-2.

O.H.: Is it possible to use a public bockchain infrastructure and, at the same time, address the privacy concerns in the aerospace industry?

L.R.G.: We’ve found a way to integrate a hybrid model of privacy while leveraging public chains. On the flip side, we do offer build outs of private infrastructure that can be available just to the client’s network. Its wholly up to the necessities of the mission and we pride ourselves in our ability to adapt.

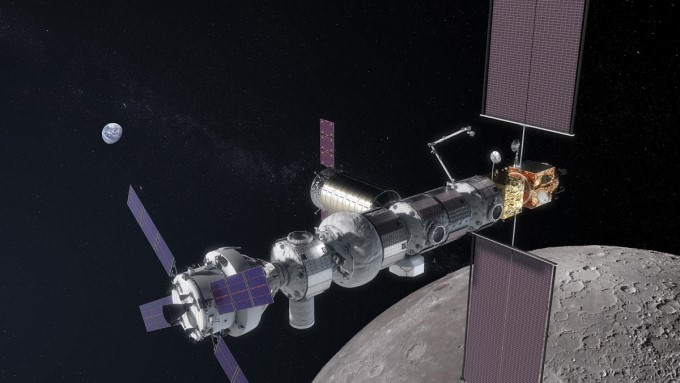

O.H.: Is the cislunar space the first step? Does Lunargistics have plans to expand beyond that?

L.R.G.: I’d say if we can manage the market on Earth’s Cislunar space we’re doing good. Lunargistics doesn’t just have to be our Moon though. We’d love to scale to Titan or Europa when the timing is right.

V.S.: Even in the dawn of next decade we may have begun our plans of working with NEO mining companies and fulfilling needs of our the Econosphere. Our expert team has enough time to plan giving a robust buffer which will help us reach the desired goals.

O.H.: What does the near future hold for Lunargistics? Can you share any exciting plans with our readers?

L.R.G.: We’re hard at work onboarding the team that will bring us closer to our goals. As a ‘New Space’ company we’re excited to be accepted into the community by your readers.

Any aerospace companies that want to understand blockchain while keeping focused on their own mission should email us at partnerships@lunargistics.lu.

We’re also hiring! So suit up for the next mission and submit your CVs to careers@lunargistics.lu!

Subscribe to blog posts using RSS

Subscribe to blog posts using RSS